By Billy Sveen

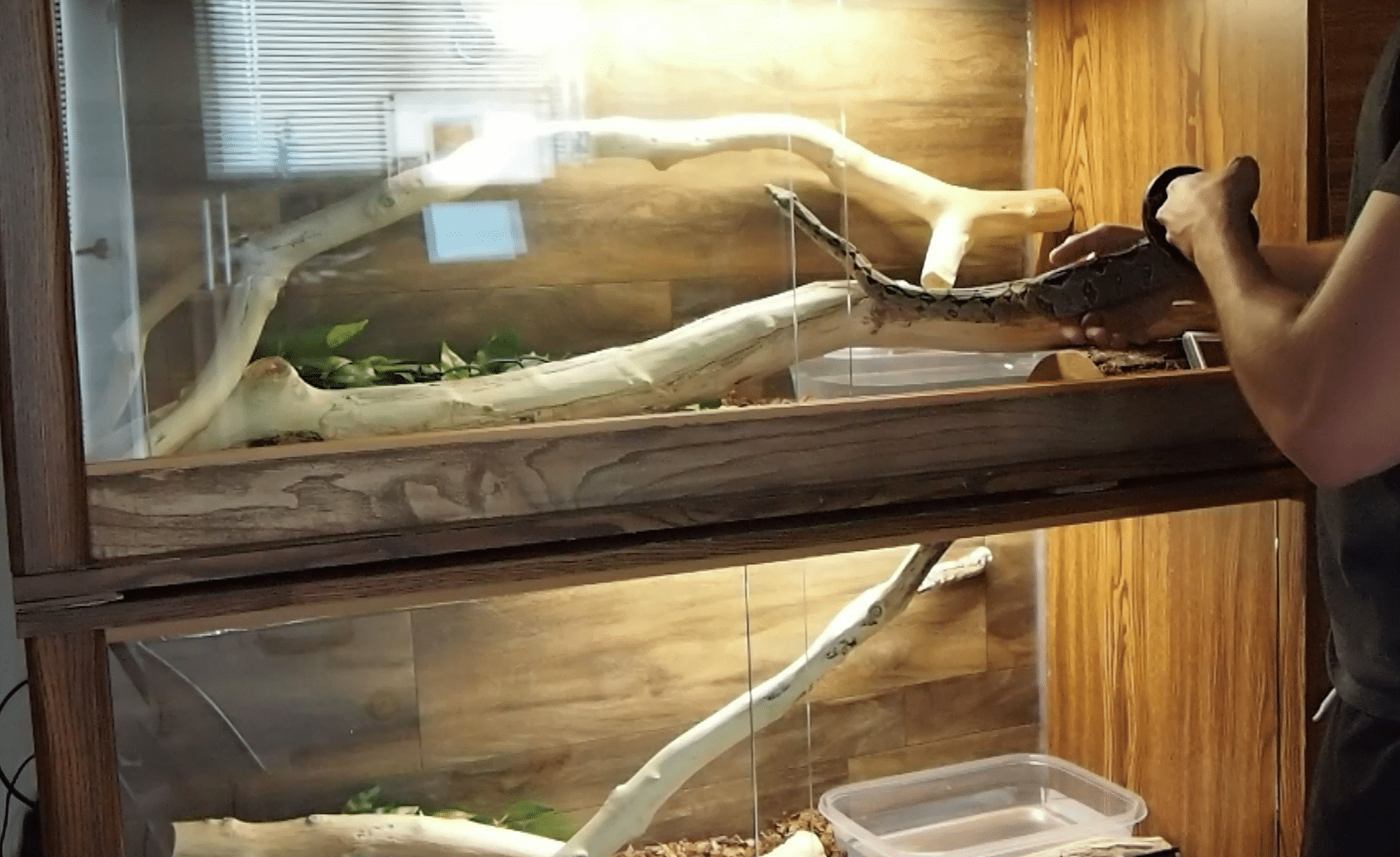

Billy Sveen is a herpetoculturalist, physician, and bioethicist living in Minneapolis, Minnesota. Follow him on Instagram at @creepersherpetoculture

As a reptile and amphibian enthusiast, maintaining accurate records of your captive population is important to monitoring health and tracking significant events, whether you keep a single animal or operate large breeding groups. However, organizing data efficiently can be a daunting task. Fortunately, technology can help. In this blog post, I’ll explore a streamlined and customizable DIY method of data entry using Google Forms on your phone and collecting the results in Google Sheets, perfect for herpetoculturalists looking to maintain accurate records of their collections. It’s also free to use for anyone with a Google account and a smartphone. I’ll be showing the basic steps, but YouTube guides are readily available for any details on how to use specific features of Forms or Sheets.

1. Creating Google Forms for Data Entry

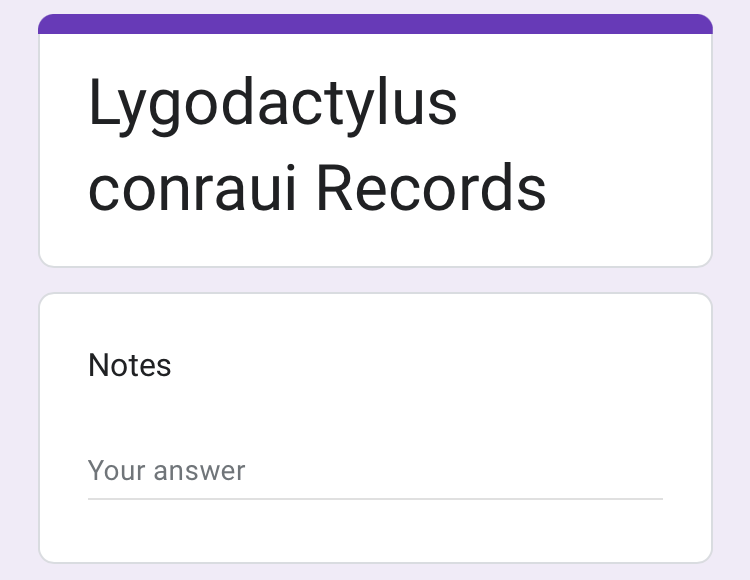

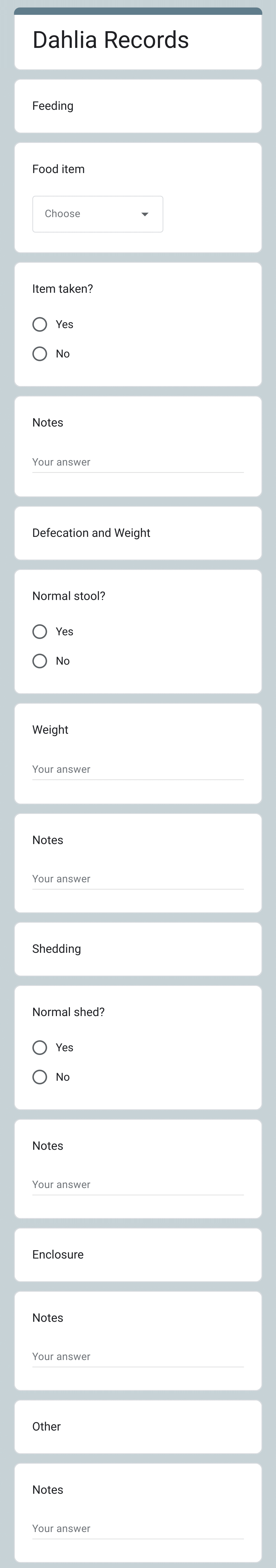

The first step is to create Google Forms tailored to your specific needs. These forms can be as simple or as complex as you want and are easy to modify at any time. You can add multiple choice, drop-down selections, and free text as needed. For example, the form for my ball/royal python (Python regius) Dahlia includes sections many pet keepers may want on feeding, weights, shedding, stooling, and any other enclosure notes where I record changes in temperature, lighting, and humidity. By contrast, the form for my Cameroon dwarf geckos (Lygodactylus conraui) is much simpler with only a section to take general notes as I don’t track their regular feedings and don’t weigh them. One benefit of using Forms is that the date and time of each entry will be automatically recorded, so you won’t need to track that specifically if you use them in real-time, but I always have at least one option for free text notes where I can note a late entry.

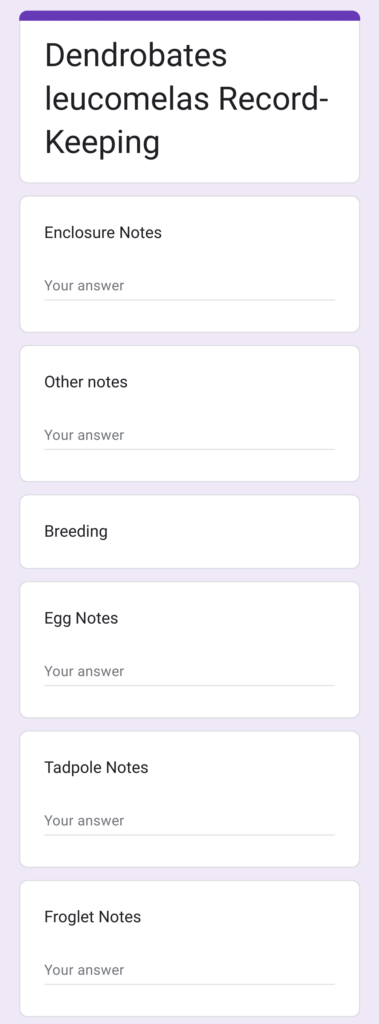

The form for my yellow-banded poison dart frogs (Dendrobates leucomelas) was similarly simple until they started breeding. Once they started reproducing, I easily added sections to track eggs, tadpoles, and froglets. Initially, I added separate areas for the number of total eggs, the number of infertile eggs, the hatching of individual tadpoles, etc., but I quickly found this too cumbersome, so I easily streamlined the form a few weeks later.

The possibilities here are endless. I have one form to broadly track my invertebrate feeder colonies and another to detail every plant I obtain, where I obtain it, how I quarantine it, etc. A pet keeper with an elaborate enclosure or two may want much more detailed notes while a professional breeder may want a physical card system to track feeding breeders and hatchlings but may want forms to track pairings and incubation data.

2. Accessing Forms via Smartphone Shortcuts

Once you set up a form, the next step is to make data entry quick and convenient. I suggest creating shortcuts on your smartphone for each form. This allows you to access the forms immediately while tending to your animals. Recording information promptly minimizes the chance of forgetting crucial details.

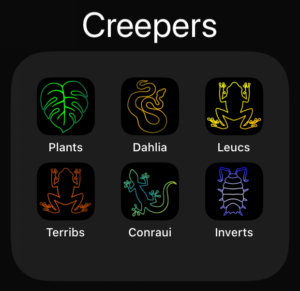

The first step is to get the URL for the form. When viewing the form, click the “Send” button and either copy the link or email it to yourself. Next, open the website in a browser on your phone and add it to your home screen as a website shortcut. Android users will be able to customize the icon in this process, but iPhone users will have to use a slightly more involved Shortcuts app to make custom icons instead of having the default icon associated with the Google Forms website. Once you make the shortcuts, you can group them together in one folder or hide them all together and search for them as needed.

For those working alone, shortcuts on your smartphone can be sufficient. However, if you have others assisting with your collection, you can take it a step further by generating QR codes for each form’s link. Placing these QR codes on the enclosures makes data entry accessible for an entire team without having to enter the shortcuts into their phones.

3. Linking Data to Google Sheets

The real power comes from linking all the data collected from the forms to Google Sheets. To do this, first access a form from which you want to import data. Then click on the “Responses” tab at the top of the page. Next, click “Link to Sheets” where you can create a new spreadsheet or link it to an existing spreadsheet. Repeat this with all of your forms.

If you have a small to medium-sized population of animals like me, you’ll probably like to have all your data as separate sheets within the same file. For example, I’ve titled my file “Creepers Herpetoculture Records” and then have separate sheets for each of my forms. If you have a large or commercial operation, you may want multiple files separated by species or room or something else.

Once in the linked Google Sheet, you can see that sheets actively linked to forms have a purple form icon. This means that these sheets will automatically update every time you enter new data through the corresponding form. Every submission is a separate line. If you change the form, new columns are added so you don’t lose data in the sheet either. However, you can manually edit or delete data in the sheets.

4. Organizing and Analyzing Data

Now that your data is easy to enter, store, and find, what do you do with it? Well, if you want a specific detail such as the last weight of your snake, you can simply look it up. This is incredibly valuable to reference but doesn’t tell you trends. Furthermore, the raw data in the sheets is not particularly easy to interpret because it’s hard to read. To fix this, you can add specific sheets to track topics that are important to you.

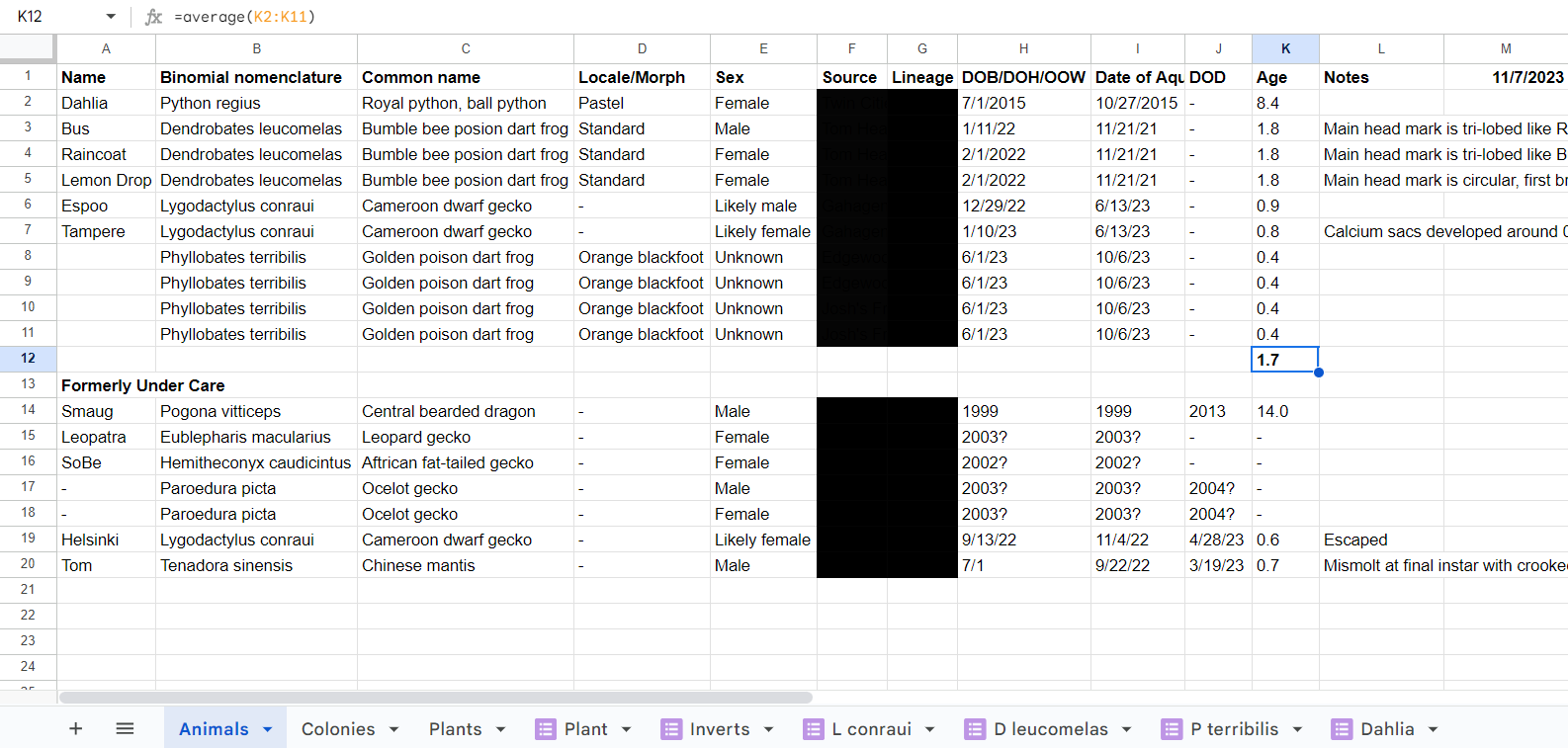

I am most interested in a detailed roster of all my animals, invertebrate colonies, and plants so I have separate pages for each of them. On the animal page, every animal has its own row. The columns are the animal’s name, scientific and common names, locale or morph info, sex, source and lineage info (blacked out for privacy), date of birth, date of acquisition, and age. I also keep a section of notes where I track anything significant about the animal. I also track animals I formally kept down lower in the same sheet and record the date of death as appropriate for those as well. The invertebrate sheet is similar but I only track colonies as a whole, not individual animals.

One benefit of using spreadsheets is the ability to use functions which are equations ranging from simple arithmetic to complicated if-then coding and statistical analysis. For example, the age of each animal is automatically updated every time I open the file. One cell (M1) has the Today function “=TODAY()” which will update with today’s date. Since spreadsheets think of dates as numbers, I can easily calculate the age of the first animal in years by typing “=(M1-H2)/365.25” where “M1” is the cell with today’s date, “H2” is this animal’s date of birth, and 365.25 is the average number of days in a year (don’t forget leap years!). The answer will likely have lots of decimal places, so use the formatting option to decrease the display of decimals to your desired amount without losing any of the data. I can then calculate the average of those ages by typing “=AVERAGE(K2:K11)” where “K2:K11” are the cells that contain the ages of all my animals.

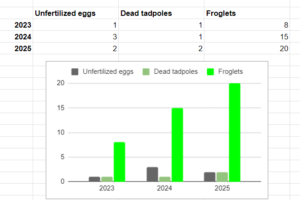

Another advantage of spreadsheets is the ability to easily make graphs. This is my first year breeding Dendrobates leucomelas poison dart frogs, and I am still figuring out what metrics I want to track. If I track how many eggs I collect, how many tadpoles develop, and how many froglets grow out, I can track any changes in reproductive success across the major stages of egg production, fertilization, and metamophorphosis. I added the relevant summary data at the end of the Dendrobates leucomelas sheet (along with data for 2024 and 2025 that I made up to illustrate the idea) and easily graphed the data to visualize trends.

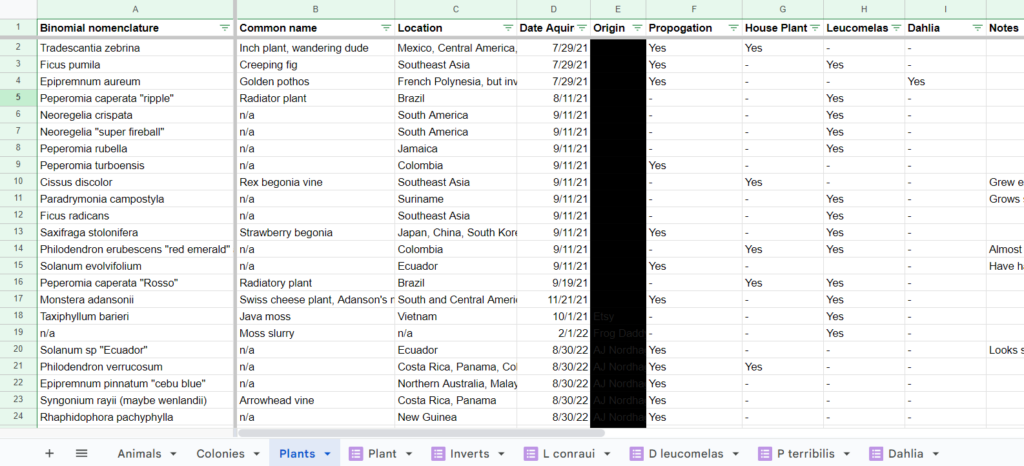

For my plants sheet, I track the scientific and common names, native location, date acquired, and source (blacked out for privacy) of each plant. Then I track where I currently have each plant, whether it’s currently in a propagation bin, in one of the animal enclosures, or as a house plant. Since I track any new plants in my Plants Form and update any new or lost plants in the relevant animal forms when I do enclosure maintenance, these lists are easy to maintain. Similar to the animal sheet, I keep track of the plants I used to have lower down on the same sheet and note any reasons why I lost them.

The possibilities for application are endless. You could chart the growth of a single animal or the productivity of a commercial breeding project. You could track feeding success based on the food type offered for hatchling snakes. You could summarize husbandry and incubation parameters for each breeding season and the relevant outcomes. You could do basic pedigree mapping and calculations of inbreeding coefficients for a breeding program. I’d love to hear what other ideas you have!

Conclusion

In conclusion, this system of using Google Forms and Sheets is a valuable tool for herpetoculturalists who want to maintain organized and up-to-date records of their captive populations. It offers speed, ease of customization, and adaptability, making it a versatile solution for keeping track of your beloved animals. Whether you’re a seasoned collector or just starting out, this method can help you better understand and care for your animals and evolve with you as you continue to advance in your practice.

Billy Sveen is a herpetoculturalist, physician, and bioethicist living in Minneapolis, Minnesota. Follow him on Instagram at @creepersherpetoculture.